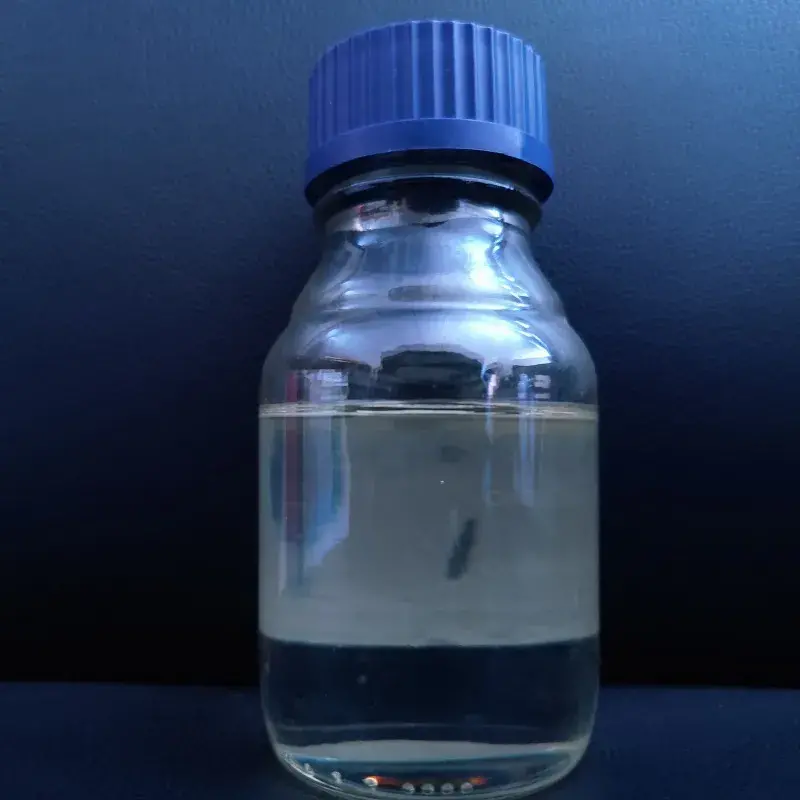

product

High-quality Epoxy Resin

about us

About factory description

what we do

Founded in 2004 and located in Tai’an, China, Tervan is a professional manufacturer of high-quality epoxy resin. The products mainly cover four series of Novolac Epoxy Resin, Bisphenol F Epoxy Resin, Bisphenol A Epoxy Resin and Modified Epoxy Resin, with business spanning over more than 50 countries and regions around the world.

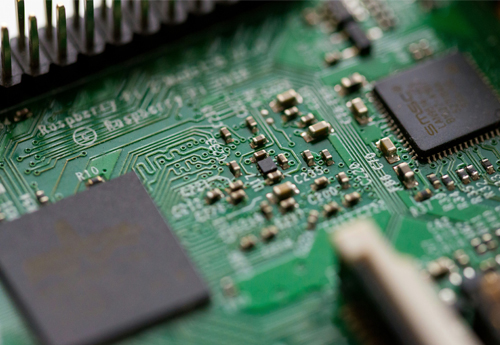

Tervan is committed to the R&D and production of ultra-high purity epoxy resin, to provide high-quality products and services for downstream customers, helping to promote technological progress in applications as high-end electronic electrical appliances, composite materials, adhesives, and coatings, etc.

Driven by the goal of “To be advanced level in the world, to be first-class in China”, Tervan actively pursues the mission of “seeking happiness for employees, seeking development for the enterprise, and contributing to society”, adhere to the road of high-quality development, and dedication to the community and the epoxy resin application industry to contribute to the sustainable development of the industry.

-

PERSONNEL

Professional research and development, production, and sales personnel provide customers with high-quality products and premium services.

-

RESEARCH

China High-quality Epoxy Resin Technology Research and Development Center, ISO certified.

-

TECHNOLOGY

Provide customized products and services according to customer demands.

application

-

3000

3000

Lorem ipsum

-

3000

3000

Lorem ipsum dolor

-

3000

3000

Lorem ipsum dolor sit ame consectetur

-

3000

3000

Lorem ipsum dolor sit amet

-

3000

3000

Lorem ipsum dolor sit

news